Rubber injection

When using rubber injection molding, the rubber compound is pumped directly into the mold for vulcanization from the barrel.

Rubber injection molding has the advantages of having a quick molding cycle and excellent production efficiency despite being an intermittent activity. the amount of labor required is little, and the quality of the finished product is superb.

injection molding

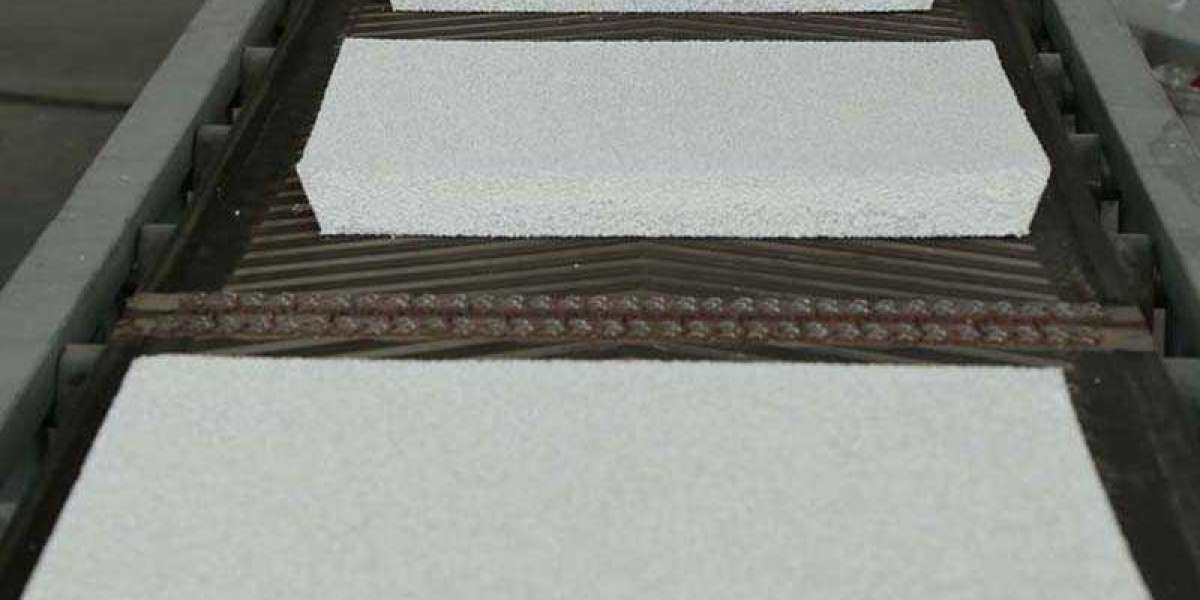

A technique for making plastic objects is plastic injection molding. The desired plastic parts are created by cooling and shaping the molten plastic after it has been pressure-injected into the mold for plastic items.

For the purpose of performing injection molding, mechanical injection molding machines exist. Polyethylene, polypropylene, ABS, PA, and polystyrene are among the plastics that are used the most frequently.

Frequently, the resulting shape is the finished item; no additional processing is needed before installation or usage as a finished item. Many small parts can be formed in one step of injection molding.

You may get the injection molding service you require from JTR.