porous ceramic filter is authorized by www.adtechamm.com to sell alumina foam ceramic filters to local aluminum smelters and foundries in Iran.

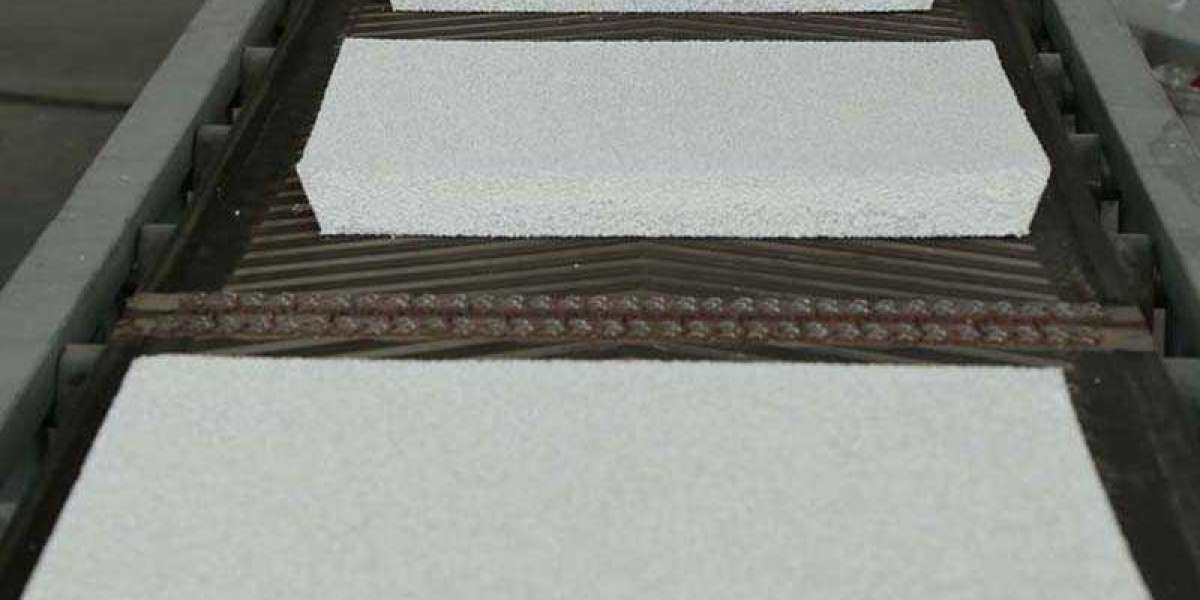

The alumina porous ceramic filter is installed on the CFF BOX machine to filter the liquid impurities of the aluminum alloy to cope with the high added value and high technical performance of the aluminum alloy in the precision casting production of transportation and transportation.

Casting Filter Agent must understand that the quality of aluminum melt is very important, it strongly affects the performance of the next processing and the quality of the final product. Therefore, all countries in the world have a great desire for the refining of aluminum melt.

There are many reasons for aluminum pollution. On the one hand, during the melting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, which is easily oxidized, easily reacts with water vapor to absorb hydrogen, and easily forms various non-forms. -Metal slag (such as coated parts, chlorides, and carbides in flux, etc.) and large intermetallic particles.

On the other hand, some waste products that constitute the charge will introduce some non-aluminum impurities during the recycling process.

Because the waste comes from process waste, geometric waste, and off-site waste from various factory processes, the route is different, the composition is complicated, and the quality is not high.

These impurities often generate bubbles and inclusions in the slab, which seriously affect the purity of the molten metal, and further affect the processing performance, mechanical properties, corrosion resistance, and product appearance quality.

Nowadays, there are many ways to remove these harmful substances and purify molten aluminum.

The different methods, these methods can be divided into two categories: in-furnace purification and continuous out-of-furnace treatment (that is, online treatment).

According to different functions, it can be divided into main degassing or slag removal. porous ceramic filter (www.adtechamm.com) introduced the use of porous ceramic filter plates to continuously filter molten aluminum. External continuous treatment, the main purification operation is slag removal.

The ceramic filter for casting has a certain strength mesh structure, which can withstand the pressure difference of the metal liquid surface and the impact of the metal flow, but it is fragile and fragile. Because this material has a precise structure, uniform quality, wide surface, and excellent filtering effect.