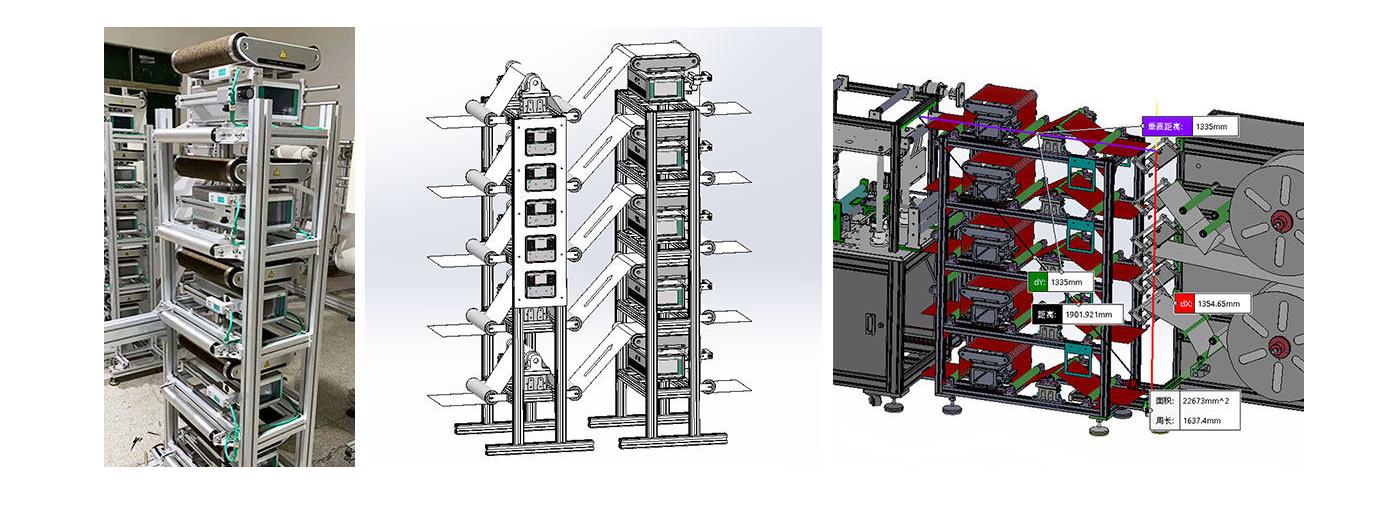

Web guide system can be widely used in various production processes of steel, corrugated paper, non-woven fabric, textile, printing, labeling, plastic film, building materials, etc. It can ensure continuous, precise control of the edges of the coil materials. Now we introduce useful tips about how to test the web guide system and daily maintenance.

How to test the web guide system

After the web guide system has been installed on the machine:

1. let the machine run first, if there is a deviation, adjust the upper layer of fabric firstly. For example, if it is to the left, it needs to be adjusted to the right. In the same way, if it turns to the right, you must adjust to the left.

2. Before turning on the web guiding machine, make sure that the fabric is aligned.

3. Then turn on the web guide equipment. After identifying the fabric, the probe is aligned with the red dot and the upper line is aligned with the edge. Then tighten the lower screw and the position will be located.

4.After locating the position, press the button of “automatic” mode. If there is an offset, it will all be aligned with the upper line.

5. Each layer is the same, and this layer should also be aligned with the red dot. The lower screw must be loosened firstly, and then the probe can be moved and aligned with the red dot.

6. After aligning the red dot and twist the black screw.

7. Then touch the “automatic” mode. If there is a deviation, the machine will swing and automatically correct it.

8. All the systems keep the "automatic" mode. Now the web guide runs automatically, and the machine will not run off when it starts.

Daily maintenance of the web guide system

Before the web guide system work

1. Check carefully whether the power switch and the indicator light of the web control system are normal.

2. Check whether the electric indicator light is normal and the sensitivity of the electric eye and the motor.

3. Whether the magnetic powder brake can be braked in time.

4. Fill the gear contact position with lubricating oil to maintain the lubrication between the wheels and reduce mechanical wear to ensure the precision of the web guide.

During the work of the web guide system

1. Is there any abnormality in the coordination of the electric eye, the control system, and the motor?

2.Listen to the sound, whether there is noise or excessive noise in the mechanical part.

3.Whether the temperature of the motor is too high.

After the work of the web guide machine

1. Turn off all power sources to prevent the rectifier from being on standby at any time.

2. Close the protective cover of the web guide control device to avoid objects hitting the device or damaging the control panel.

3. Protect the electric eye from damage by external objects.

4. Lubricate the motor bearings and screw rods.

5. Add lubricant to gears and magnetic powder brakes.

For more professional knowledge, please visit the page of web guide articles