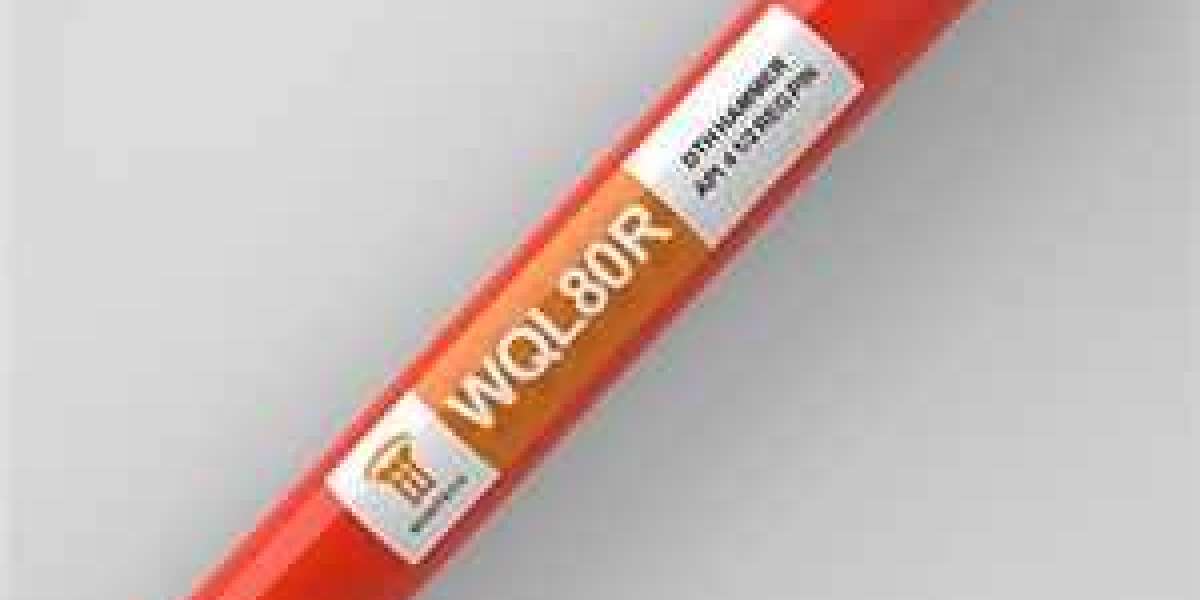

Original title: What are the drill bits of pile drivers and rotary drilling rigs? What type of drill bit is suitable for your site? I often hear customers ask the service manager of Zhongyi Huilong pile driver and rotary drilling rig, what should I do if my site encounters quicksand? What should I do if I encounter a rock layer while drilling? At that time, these questions are very simple, as long as you know how to use the drill bit of the rotary drilling rig. Today, Zhongyi Huilong Pile Driver and Rotary Drilling Rig will introduce us to our common rotary drilling bits, mainly including spiral drilling bit, rotary bucket, barrel coring bit, underreamer bit, percussion bit, percussion grab cone bit and hydraulic grab bucket. The following is a brief introduction. 1.1 Auger bit (1) Conical: double head double screw,dth drilling hammer, suitable for hard bedrock. Double-headed single screw, suitable for weathered bedrock, pebbles, frozen soil with ice, etc. The above drill bits are equipped with various picks,rock drilling tools, and many types of drill bits can be derived through the changes of tooth type, pitch and helix angle. (2) Straight spiral bit: A. Bucket tooth straight screw: double-headed double screw, applicable to sandy soil and poorly cemented small-diameter gravel layer; double-headed single screw, applicable to sandy soil and soil layer; single-headed single screw, applicable for poorly cemented large-diameter pebble, cohesive soil and hard clay. B. Pick straight screw: double screw, triple screw and quadruple screw, suitable for hard bedrock or gravel. 1.2 Rotary drilling bucket Expand the full text According to the installed teeth, dhd drill bit ,dth drill bits, it can be divided into pick drilling bucket and bucket tooth drilling bucket; according to the number of bottom plates, it can be divided into double-layer bottom bucket and single-layer bottom bucket; according to the number of door opening, it is divided into double-door opening bucket and single-door opening bucket; according the taper of the barrel, it is divided into conical barrel drilling bucket and straight barrel drilling bucket. According to the shape of the low plate, it has been divided into pan bottom drilling bucket and flat-bottomed drilling bucket. The above structural forms are combined with each other, and with the change of whether to have a vent hole and a door opening mechanism, dozens of rotary drilling buckets can be combined. Generally speaking, the double-bottom drilling bucket is applicable to a wide range of strata, and the single-bottom drilling bucket is only applicable to the soil layer with strong viscosity. The double-door drilling bucket is applicable to a wide range of strata, and the single-door drilling bucket can only be used for large-diameter pebbles and hard clay. 1.3 Barrel type core bit At present, there are two common ones: cutter barrel drill (suitable for medium hard bedrock and gravel) and roller barrel drill (suitable for hard bedrock and large boulders). In the two types of barrel coring drill, there are two types of bit with coring device and without coring device, which mainly depends on the difficulty of coring. Because the cone coring bit is mainly used for hard rock drilling, and the annular area of drilling is large, if conditions permit, reverse circulation drilling can be added to the bit part to improve the drilling efficiency. 1.4 Underreamer bit On the basis that the pile diameter is not increased and the pile depth is not increased, in order to improve the bearing capacity of a single pile, the design department often uses a belled pile. The construction of belled pile by a rotary excavator can be carried out without any change, and only a belled drill bit is selected. The under-reamed bit is mainly mechanical, which is relatively simple to use and maintain. There are up-opening and down-opening bits, and the opening mechanism is generally four-link, which is used for soil, strong wind, moderately weathered strata and even hard bedrock. Because the rotary drilling is a non-circulation drilling, the slag can be removed with a slag removal bucket after the bottom expansion is completed. 1.5 Percussive drill bit and percussion grab drill bit When drilling large-diameter pebbles, large boulders and hard bedrock, it is particularly effective to use percussion drill bits and percussion grab cone drill bits in combination with rotary drilling. Such drill bits are used by hanging the auxiliary hook of the rotary drilling machine. Because of the impact effect, the auxiliary hook is required to have the function of free rope release to achieve better results. 1.6 Hydraulic grab At present,mining drill bit, there are more and more construction projects of diaphragm wall and anti-seepage wall. If the rotary drilling rig is slightly changed, it can work. The opening and closing of the hydraulic grab bucket is driven by hydraulic pressure. There is only one oil cylinder on the hydraulic grab bucket, so only two oil pipes and one control valve are needed. Return to Sohu to see more Responsible Editor:. wt-dthtools.com

KathleenJHarr

8 Blog posts