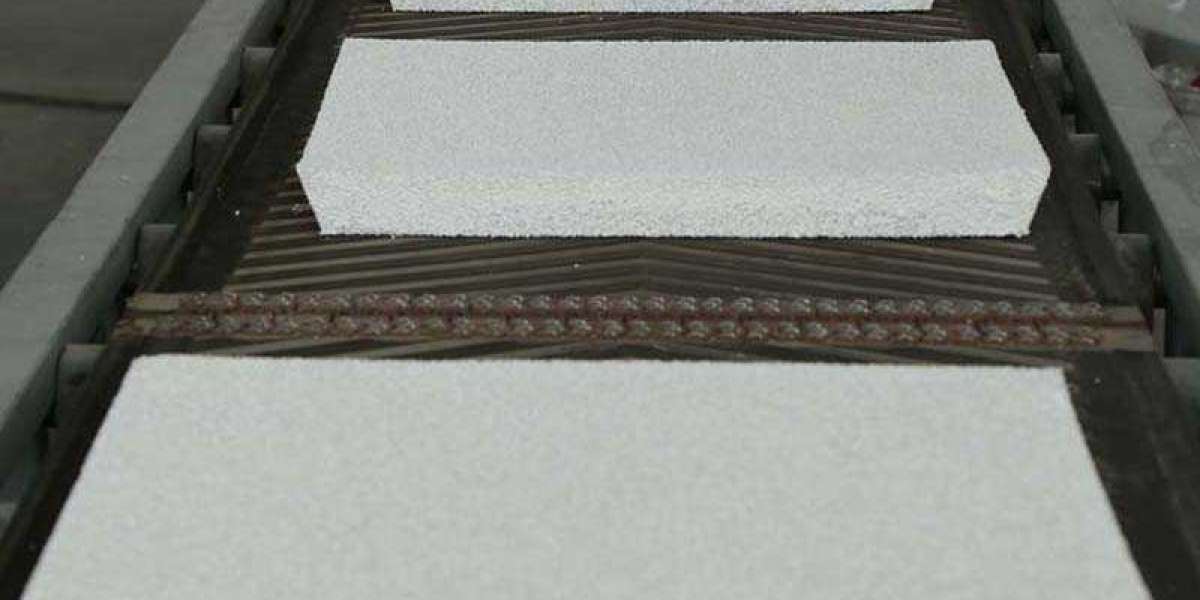

porous ceramic filter out can efficaciously put off huge inclusions in molten aluminum and adsorb micron-sized particles of inclusions, which may improve floor first-class, enhance product performance, enhance microstructure, and increase yield.

it is widely used inside the production fields of aluminum profile, aluminum foil, aluminum alloy, and so on.

The slag inclusion defects inside the castings substantially affect the manufacturing efficiency and financial blessings of the iron casting plant.

Coarse inclusions on the surface lessen the surface finish of the casting and reason the casting to be at once scrapped in severe cases.

Inclusion defects below the skin are commonly determined simplest inside the processing level, meeting stage, or real use level.

for example, in the processing workshop, the lifestyles of macroscopic or microscopic inclusions will reduce the machinability of castings and the existence of machining equipment.

The inclusions that exist during a meeting or during the provider will lessen the mechanical properties or provider performance of the casting, including inflicting leakage under strain.

Castings scrapped for the duration of processing, meeting, or use typically motivate higher losses due to the fact E has accomplished more than one operation before.

inside the practice of casting production, filtration performance may be used to evaluate the purification impact of porous ceramic filter clear out on liquid casting alloys.

Samples had been taken from the pinnacle and bottom of every casting within the equal warmth or the equal ladle of molten steel to decide the cleanliness of the filtered and unfiltered castings.

Use an optical microscope and a scanning electron microscope to analyze the inclusion meeting location.

The shape, size, and length distribution of the inclusions were determined with a photo analyzer, and the attention of the inclusions became quantitatively analyzed by using extraction and gravimetric evaluation.

recall the usage of the vicinity of the slag-gathering oxide as the evaluation sample cleanliness, size, and the cleanliness of the solid alloy is the location ratio of the slag-gathering oxide in keeping with the unit weight of the sample.

The filtration efficiency is the percentage of the ratio of the oxide floor location difference according to the unit weight of the sample earlier than and after filtration to the oxide surface area of the pattern before filtration.

The setting of the porous ceramic clear out must no longer most effectively acquire the nice filtering impact however additionally hold the molten steel flowing at the right glide fee. for this reason, the region ratio between the gate and the porous ceramic filter outplacement function should be proportional.