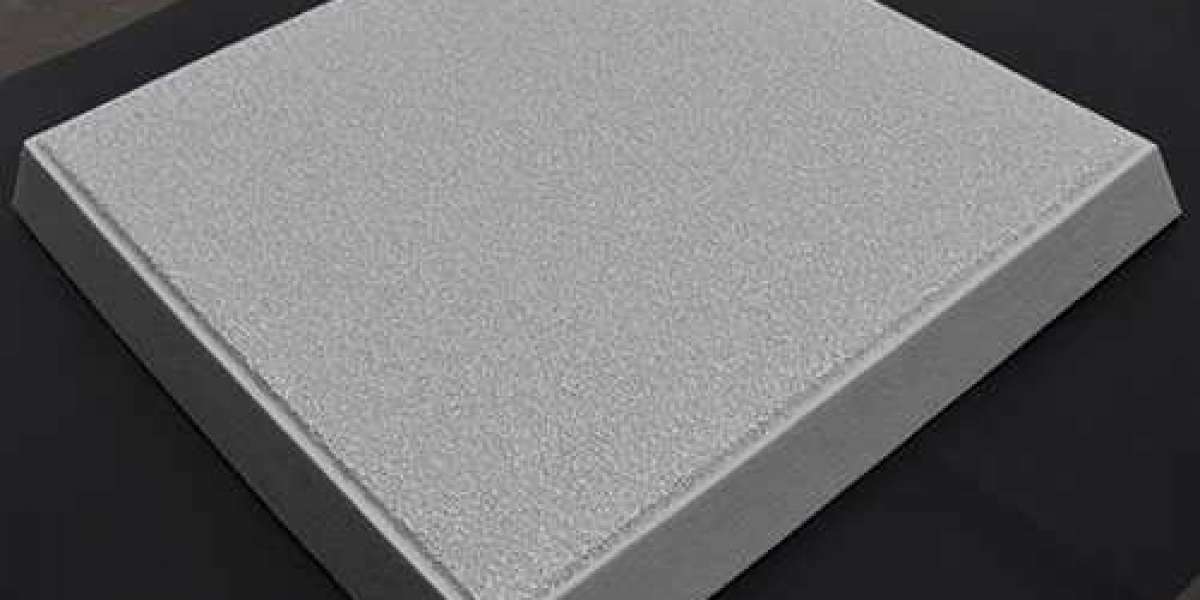

Ceramic foam filter Iceland consist of many homogeneous micropores. As the fluid passes through these pores, suspended solids, colloidal particles and large organic molecules are trapped on the surface of the filter medium.

The fluid produces various physical effects through the microporous channels, realizing mechanical screening, purification or diffusion, fluidization and other functions.

Foundry ceramic filter plate has the advantage of corrosion resistance high temperature resistance, high mechanical strength, no harmful substances leaching, no secondary pollution, micro hole under the action of fluid pressure without deformation, easy cleaning regeneration, long service life, new filtration technology, novel design, simple structure and other characteristics, economic and practical.

With the development of automobile industry, more and more aluminum alloy castings are used, and the requirements for castings are higher and higher.

In addition to ensuring chemical composition, mechanical properties and dimensional accuracy, aluminum alloy castings are not allowed to have shrinkage holes, shrinkage holes, pores, slag holes and other casting defects.

Ceramic foam filter Iceland is one of the measures to ensure the quality of aluminum alloy products, but also the main means to improve the overall quality of aluminum alloy.

The refining effect of liquid aluminum has an important effect on the formation of pores, shrinkage pores and inclusions in aluminum alloy castings, which directly affects the physical and mechanical properties of aluminum alloy castings.

Without high quality liquid aluminum, defects will always exist in the product even after subsequent processing, making it difficult to obtain high quality castings.

Therefore, we must pay attention to the gas and inclusion in the liquid aluminum, and take measures to remove the gas in the liquid aluminum. With the development of automobile industry, more and more aluminum alloy castings are used, and the requirements for castings are higher and higher.

In addition to ensuring chemical composition, mechanical properties and dimensional accuracy, aluminum alloy castings are not allowed to have shrinkage holes, shrinkage holes, pores, slag holes and other casting defects.

Liquid aluminum purification ceramic foam filter Iceland is one of the measures to ensure the quality of aluminum alloy products, but also the main means to improve the overall quality of aluminum alloy.

The refining effect of liquid aluminum has an important effect on the formation of pores, shrinkage pores and inclusions in aluminum alloy castings, which directly affects the physical and mechanical properties of aluminum alloy castings.

If there is no high quality liquid aluminum, even if the subsequent treatment, once the defects will always exist in the product, it is difficult to obtain high quality castings.

Attention must be paid to gases and inclusions in liquid aluminum, and measures must be taken to remove them.